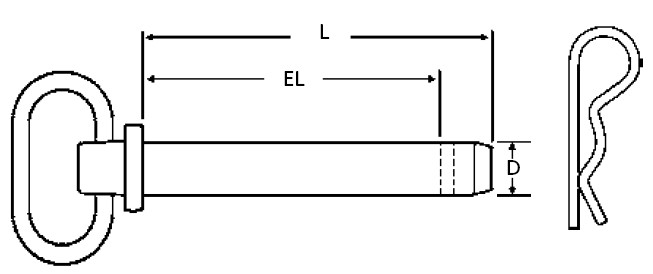

| PART NO. | Nominal | Effective Length | Overall Length | WEIGHT | |

| (D) | (EL) | (L) | |||

| INCH | MM | INCH | INCH | KG/PCS | |

| HP050-400R | 1/2 | 1/2 | 4 | 4-3/4 | 0.173 |

| HP050-575R | 5-3/4 | 6-1/2 | 0.218 | ||

| HP625-400R | 5/8 | 1/6 | 4 | 4-3/4 | 0.291 |

| HP625-500R | 5 | 5-3/4 | 0.327 | ||

| HP625-575R | 5-3/4 | 6-1/2 | 0.336 | ||

| HP625-600R | 6 | 6-3/4 | 0.364 | ||

| HP750-400R | 3/4 | 20 | 4 | 4-3/4 | 0.395 |

| HP750-425R | 4-1/4 | 5 | 0.400 | ||

| HP750-525R | 5-1/4 | 6 | 0.455 | ||

| HP750-625R | 6-1/4 | 7 | 0.509 | ||

| HP875-425R | 7/8 | 22 | 4-1/4 | 5-1/4 | 0.545 |

| HP875-625R | 6-1/4 | 7-1/4 | 0.686 | ||

| HP875-650R | 6-1/2 | 7-1/2 | 0.709 | ||

| HP875-700R | 7 | 8 | 0.773 | ||

| HP100-425R | 1 | 25 | 4-1/4 | 5-1/4 | 0.686 |

| HP100-475R | 4-3/4 | 5-3/4 | 0.750 | ||

| HP100-625R | 6-1/4 | 7-1/4 | 0.924 | ||

| HP100-675R | 6-3/4 | 7-3/4 | 1.000 | ||

| HP100-700R | 7 | 8 | 1.020 | ||

| HP1125-700R | 1-1/8 | 28 | 7 | 7-3/4 | 1.230 |

| HP1250-700R | 1-1/4 | 32 | 7 | 7-3/4 | 1.510 |

| HP1375-800R | 1-3/8 | 35 | 8 | 9 | 2.160 |

| HP1500-800R | 1-1/2 | 38 | 8 | 9 | 2.500 |

Forged hitch pins are strong, durable fasteners commonly used to secure towing and trailer components, ensuring a secure and reliable connection between vehicles, trailers, and other equipment.

These pins are forged for added strength, durability, and reliability, making them suitable for heavy-duty applications.

Here are some key applications of forged hitch pins:

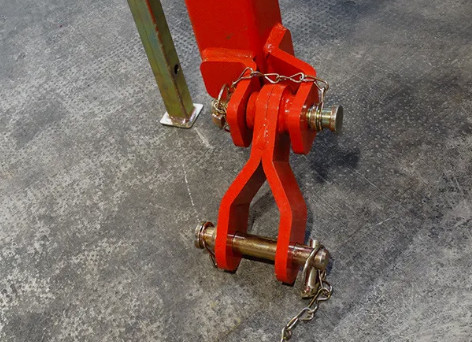

Tractor Implements: Forged hitch pins are commonly used to attach various agricultural implements to tractors or other machinery. The hitch pin design ensures a secure attachment that can handle the heavy loads and vibrations typically encountered in farming operations.

Tillage and Cultivation Equipment: Similar to other agricultural attachments, forged hitch hook pins are used to keep parts of the equipment connected while withstanding the rough conditions of farming.

Trailer Hitches: Forged hitch pins are used in trailer hitching systems, ensuring that the tow bar or hitch is securely fastened to the towing vehicle. Forged hitch pin design allows for a stable and locked connection that minimizes the risk of detachment during transport.

Truck and Trailer Connections: In commercial trucking and logistics, hook pins can secure parts of a trailer's coupling mechanism, helping to safely connect the trailer to the tractor or truck.

Excavators and Backhoes: Forged Hitch pins are used in construction machinery to secure buckets or other attachments to the main body of the machine. These pins are essential for maintaining the structural integrity of the equipment under heavy loads and challenging conditions.

Loader Attachments: In loaders and skid-steer machines, Forged hitch pins provide a reliable method to attach various implements, such as buckets, forks, or blades, ensuring efficient and safe operation.

Heavy-duty Equipment Connections: Forged hitch pins are essential in industrial applications where high-strength, secure connections are needed for parts of machinery that frequently undergo stress, impact, or vibration.

Tensioning or Stabilizing Systems: In some machines, forged hitch pins help stabilize or lock tensioning systems in place, such as those found in large rollers or conveyor belts.

Boat and Docking Equipment: Forged hitch pins can be used in marine environments to secure boats to docks or other equipment. They provide a robust solution to keep components tightly connected in harsh, salty environments where corrosion resistance is also important.

Cargo Securing: Forged hitch pins are also employed in securing cargo to ships, ensuring the load is safely locked in place during transit.

Overall, forged hitch pins are essential components in industries that rely on heavy-duty equipment and safe, secure connections. Their strength and durability make them suitable for high-stress applications across a wide range of sectors.

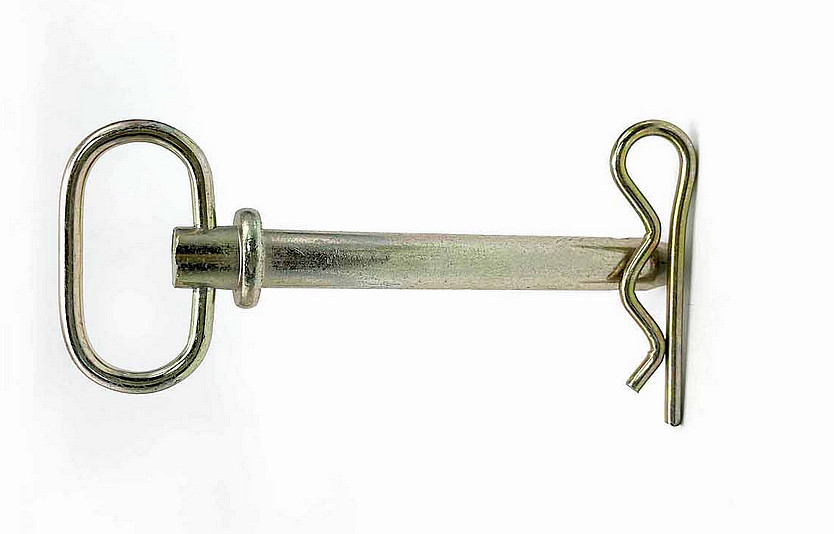

A forged hitch pin is a heavy-duty component typically used in towing and trailer applications to secure a trailer or towing accessory to a vehicle's hitch receiver.

Forging is a manufacturing process that involves shaping metal using compressive force, which results in a stronger, more durable product.

The main features of a forged hitch pin include:

Protective Coatings: Many forged hitch pins come with protective coatings such as zinc plating, powder coating, or stainless steel finishes to help prevent rust and corrosion, especially in outdoor or harsh weather conditions.

Uniform Size and Shape: Forged hitch pins are typically manufactured to tight tolerances, ensuring they fit securely into the hitch receiver and provide a stable connection between the vehicle and trailer.

Custom Sizes Available: They are often available in various sizes and diameters to fit different hitch receivers and towing applications.

Locking Mechanisms: Many forged hitch pins feature locking mechanisms to prevent the pin from accidentally coming loose during towing. This adds an extra layer of security to the connection.

Anti-Rattle Features: Some forged hitch pins are designed to reduce or eliminate movement between the pin and hitch receiver, which helps prevent rattling during transport.

Multiple Applications: While primarily used for trailers, forged hitch pins can also be used in other towing setups, such as bike racks, cargo carriers, and tow bars.

Compatible with Various Hitch Types: Forged hitch pins come in different configurations to work with various hitch sizes and receiver classes

Quick Installation and Removal: Forged hitch pins are designed to be easy to install and remove, often with simple mechanisms like spring-loaded clips or quick-release pins.

Ergonomic Design: Some hitch pins have ergonomic grips or handles, making them easier to handle, especially when the pin is used in cold or wet conditions.

Forged hitch pins are highly durable, secure, and versatile towing components, designed to ensure safe and reliable trailer connections. Their strength, corrosion resistance, and precision make them a popular choice for both recreational and commercial towing applications.

Ready to upgrade your hitching system? Order your forged hitch pins now and enjoy fast shipping and excellent customer service. Our team is dedicated to providing you with the best in quality and reliability!

Lynch Pins are designed with a solid pin with an attached self-locking ring. This ring allows the pin to be securely held in place and provides an easy grip for quick removal. Made of low carbon steel, zinc plated. Available in stainless steel and customization.

Flat Head Clevis Pin with Groove is a type of fastener commonly used in mechanical assemblies to connect two components, typically in applications requiring a secure, yet removable, joint. It features a flat, broad head that provides a larger surface area, ensuring stability and preventing the pin from slipping out. The groove in the pin allows for the insertion of a retaining clip, which locks the pin in place and helps prevent accidental dislodging.

Button Handle Quick-Release Pins are ideal for applications that have limited space around the handle. The stainless steel construction and smart engineering of our Quick-Release Pins resist corrosion in harsh environments. Experience quick, easy positive engagement and high holding strengths for applications requiring frequent, repetitive use.

#Handle and Button are made of aluminum.

#Shake available in carbon steel and stainless steel.

#Customization is available.

Clevis pin, a reusable, non-threaded cylindrical type of industrial pin with holes in the shank end, secures components between its head and end. Clevis pins are perfect for quickly connecting or disconnecting equipment in both temporary and permanent applications, especially when precise alignment is not necessary.

In many cases, they are used in a three-point fastening system that connects trailer hitches or agricultural attachments to larger equipment. They feature a variety of head and end styles - including chamfers, grooves, angles, etc. - that are available in different combinations, making them versatile for many different uses.