1. Round Shaft Locking Pin Material

Carbon Steel: Suitable for general-purpose applications where corrosion resistance is not a primary concern. Often zinc-plated or galvanized for some degree of rust protection.

Stainless Steel: Excellent for high-corrosion environments like marine or outdoor applications. Stainless steel provides superior durability, rust resistance, and is preferred for heavy-duty usage.

Coatings: Options include zinc plating, black oxide, or galvanized coatings, which help protect against rust and corrosion in more demanding environments.

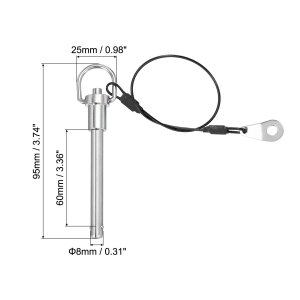

2. Round Shaft Locking Pin Diameter

The diameter of the pin is a key specification and typically ranges from:

1/8 inch (3.2 mm)

3/16 inch (4.8 mm)

1/4 inch (6.4 mm)

5/16 inch (7.9 mm)

3/8 inch (9.5 mm)

1/2 inch (12.7 mm)

The diameter must be carefully chosen to match the hole sizes of the components or equipment you’re working with.

3. Round Shaft Locking Pin Length

The length of the pin is also essential, as it needs to span the parts being fastened securely. Typical lengths include:

1 inch (25.4 mm)

2 inches (50.8 mm)

3 inches (76.2 mm)

4 inches (101.6 mm)

5 inches (127 mm)

Custom lengths may also be available depending on the manufacturer.

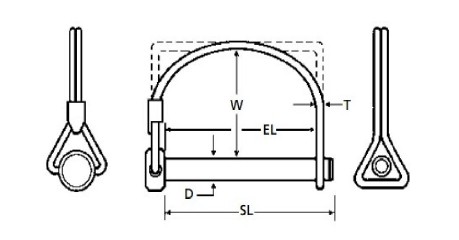

4. Wire Loop Size and Thickness

Loop Diameter: Typically, the loop at the end of the pin comes in various diameters, usually ranging from 1 inch (25.4 mm) to 2 inches (50.8 mm). The loop is often designed to be large enough to ensure easy handling and secure locking.

Loop Wire Gauge: The wire used for the loop is generally made from a high-strength material and can come in different gauges (thickness) to ensure durability and resistance to deformation.

5. Round Shaft Locking Pin Load Capacity

Round loop wire lock pins are rated for different load-bearing capacities. The load capacity can vary based on the pin diameter, material, and overall design. Typically, these pins are designed to handle moderate to heavy loads, making them suitable for both light-duty and heavy-duty applications. For example:

Small Pins (1/8" to 3/16"): Generally used in light applications and can withstand lighter loads (50-200 lbs).

Medium Pins (1/4" to 5/16"): Suitable for medium-duty applications with load capacities ranging from 200 to 500 lbs.

Large Pins (3/8" and above): For heavy-duty applications, these pins can handle loads of 500 lbs and above.

6. Round Shaft Locking Pin Types of Finish

Plain Finish: No coating, suitable for indoor applications where corrosion isn’t a concern.

Zinc-Plated: Provides some corrosion resistance, ideal for outdoor use but not highly corrosive environments.

Galvanized: Heavy-duty corrosion resistance, excellent for prolonged exposure to moisture.

Stainless Steel: Best for marine or highly corrosive environments; provides excellent rust resistance without the need for additional coatings.

7. Round Shaft Locking Pin Head Design

The pin head is typically round or flat to make it easy to push through aligned holes. Some variations may have a groove or knurled finish for better grip when installing or removing the pin.

8. Round Shaft Locking Pin Compliance Standards

Many manufacturers produce round loop wire lock pins according to industry standards, including:

1. ASME B18.8.2: Standard for pins, including tolerances for diameter and length.

2. DIN 94 / ISO 1234: Standards for split pins and locking pins, which may influence the design of round loop wire lock pins.