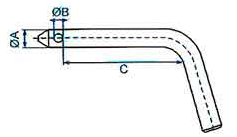

| Part Number | Pin Dia "D" (mm) |

Usable Lemgth "A" mm |

Clip Size "C"(mm) |

Hole Dia "B" |

| LF50-01 | 9.5 | 55 | 2 | 3.0 |

| LF50-02 | 9.5 | 70 | 2 | 3.0 |

| LF50-03 | 12.7 | 55 | 2 | 3.0 |

| LF50-04 | 12.7 | 70 | 3 | 4.0 |

| LF50-05 | 15.9 | 63.5 | 3 | 4.0 |

| LF50-06 | 15.9 | 76.2 | 3 | 4.0 |

| LF50-07 | 19 | 89 | 4 | 5.0 |

| LF50-08 | 19 | 102 | 4 | 5.0 |

A bent clevis pin is a type of fastener used in mechanical systems, commonly for connecting components in machinery, vehicles, and other mechanical assemblies.

It is a variation of the standard clevis pin, designed to accommodate specific alignment or rotational needs in certain applications.

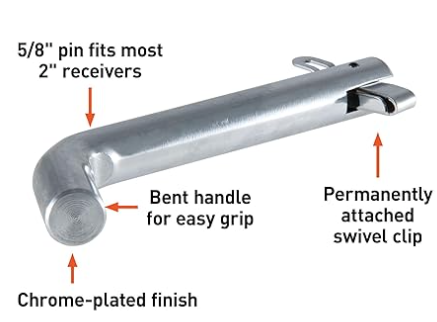

The 5/8-inch diameter of this hitch pin is compatible with any ball mount or other trailer hitch accessories with a 2-inch shank and 5/8-inch pin hole, making this receiver hitch pin a perfect fit for most class 3, 4 and 5 trailer hitches.

The 105-degree bend in this swivel trailer hitch pin creates a useful handle for easier use and allows the pin to stay securely engaged in the trailer hitch and ball mount

Protected by a durable zinc-plated finish, this tow hitch pin maintains excellent resistance to rust and corrosion for longevity and hassle-free use every time

To install this swivel trailer hitch pin, simply insert your ball mount or other hitch accessory into the receiver. With the pin holes in the side of the receiver tube lined up, insert the pin and turn the clip

Bent clevis pins are usually made from high-strength materials like steel, stainless steel, or alloy metals to handle significant loads and resist wear, corrosion, and fatigue in demanding applications.

A bent clevis pin is designed to provide angled connection capabilities, high load-bearing strength, and secure retention for mechanical systems where alignment or space constraints prevent the use of a straight pin.

It combines the functionality of a standard clevis pin with a design suited for more complex applications.

A bent clevis pin is used in a variety of mechanical systems and industries where angled connections, high load-bearing capacity, and secure fastening are required.The bend in the pin allows it to be used in applications where a standard, straight clevis pin wouldn’t fit or function effectively.

Here are some of the key applications of bent clevis pins:

Trailer Hitch Systems: Bent clevis pins are used in trailer hitch assemblies to secure the connection between a towing vehicle and a trailer. The bent pin allows for the alignment and flexibility needed in various towing scenarios.

Utility Trailers: Often used to attach components like axles, suspension parts, or drawbars, especially where space or angular alignment is an issue.

Tractors, Harvesters, and Plows: Bent clevis pins are commonly used to connect various components of agricultural machinery, such as attaching implements to tractors. The bent design allows for the necessary angle adjustments in the connection points.

Farm Equipment Linkages: Used in the linkages of mowers, tillers, and other farm tools, where components need to pivot at certain angles.

Excavators, Backhoes, and Loaders: These machines often use bent clevis pins to connect moving parts, such as boom arms, buckets, or stabilizers, allowing for flexibility in the range of motion.

Hydraulic Systems: Bent clevis pins are used in hydraulic actuators and cylinders to secure parts that move in a non-linear or angled direction.

Suspension Linkages: In vehicles, especially in off-road or heavy-duty applications, bent clevis pins can be found in suspension systems to connect parts like shock absorbers or sway bars at specific angles.

Steering Mechanisms: The bent clevis pin may be used in steering assemblies where parts must pivot at certain angles, like in the steering linkages of trucks and large vehicles.

Ready to upgrade your hitching system? Order your bent clevis pin now and enjoy fast shipping and excellent customer service. Our team is dedicated to providing you with the best in quality and reliability!

Our premium, heat treated, grade 8 performance hitch pin made from alloy steel is designed for the toughest applications.Pin has black powder coating with a blue or gray vinyl coated head and handle. Zinc plated 'R" clip pin included.

● Blue/Gray Handle Hitch Pin 1/2 Inch

● Blue/Gray Handle Hitch Pin 5/8 Inch

● Blue/Gray Handle Hitch Pin 3/4 Inch

● Blue/Gray Handle Hitch Pin 7/8 Inch

● Blue/Gray Handle Hitch Pin 1 Inch

● Blue/Gray Handle Hitch Pin 1-1/8 Inch

● Blue/Gray Handle Hitch Pin 1-1/4 Inch

● Blue/Gray Handle Hitch Pin 1-1/2 Inch

Red Head Hitch Pin is used to attach tools and machinery. It is a special purpose forged hitch pin with red protection or visibility features designed to enhance safety and functionality when towing. The forged red head hitch pin is made of high strength steel and is heat treated. The red head hitch pin is powder coated with a red vinyl coating on the head and handle and includes a zinc plated "R" clip pin.

● Red Head Hitch Pin 1/2 Inch

● Red Head Hitch Pin 5/8 Inch

● Red Head Hitch Pin 3/4 Inch

● Red Head Hitch Pin 7/8 Inch

● Red Head Hitch Pin 1 Inch

● Red Head Hitch Pin 1-1/8 Inch

● Red Head Hitch Pin 1-1/4 Inch

● Red Head Hitch Pin 1-1/2 Inch

Linkgo Clevis pins are used as a quick and secure fastener in place of bolts and rivets. Designed with both a flat or domed head on one end and cross-hole at the other, a clevis pin is inserted through the holes at the pronged ends of a clevis and is kept in place by a cotter pin. Similar to bolts and rivets, clevis pins are used as quick, secure, and cost-effective fasteners. Available in plain, zinc clear, zinc yellow, and stainless steel. Universal Clevis Pin, Cylinder pin, Adjustable Clevis pin can be reused in a variety of applications in agricultural and other industrial applications.

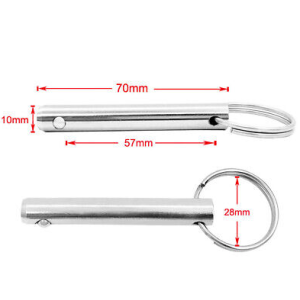

Pull Ring Detent Pins,also known as cotterless hitch pins or quick-release pins,which is a type of fastener commonly used to secure or lock parts in place temporarily. It features a detent mechanism (typically a spring-loaded ball bearing or pin) and a pull ring for easy removal.

# Material: Steel, zinc plated

# Customization Sizes are Available