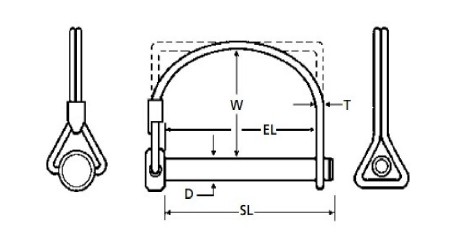

| PART NO. |

Nominal (D) |

Effective Length (EL) |

Shank Length (SL) |

Handle Style |

WEIGHT | |

| INCH | MM | INCH | INCH | R/S | KG/PCS | |

| WL250-175R | 1/4 | 6 | 1-3/4 | 2 | Round | 0.033 |

| WL250-175S | 1-3/4 | 2 | Square | 0.033 | ||

| WL250-225R | 2-1/4 | 2-1/2 | Round | 0.040 | ||

| WL250-225S | 2-1/4 | 2-1/2 | Square | 0.040 | ||

| WL250-250R | 2-1/2 | 2-3/4 | Round | 0.042 | ||

| WL250-250S | 2-1/2 | 2-3/4 | Square | 0.042 | ||

| WL312-137R | 5/16 | 8 | 1-3/8 | 1-5/8 | Round | 0.038 |

| WL312-137S | 1-3/8 | 1-5/8 | Square | 0.038 | ||

| WL312-175R | 1-3/4 | 2 | Round | 0.045 | ||

| WL312-175S | 1-3/4 | 2 | Square | 0.045 | ||

| WL312-225R | 2-1/4 | 2-1/2 | Round | 0.049 | ||

| WL312-225S | 2-1/4 | 2-1/2 | Square | 0.049 | ||

| WL312-250R | 2-1/2 | 2-3/4 | Round | 0.054 | ||

| WL312-250S | 2-1/2 | 2-3/4 | Square | 0.054 | ||

| WL375-137R | 3/8 | 10 | 1-3/8 | 1-5/8 | Round | 0.042 |

| WL375-137S | 1-3/8 | 1-5/8 | Square | 0.042 | ||

| WL375-150R | 1-1/2 | 1-3/4 | Round | 0.043 | ||

| WL375-150S | 1-1/2 | 1-3/4 | Square | 0.043 | ||

| WL375-175R | 1-3/4 | 2 | Round | 0.051 | ||

| WL375-175S | 1-3/4 | 2 | Square | 0.051 | ||

| WL375-225R | 2-1/4 | 2-1/2 | Round | 0.058 | ||

| WL375-225S | 2-1/4 | 2-1/2 | Square | 0.058 | ||

| WL375-250R | 2-1/2 | 2-3/4 | Round | 0.064 | ||

| WL375-250S | 2-1/2 | 2-3/4 | Square | 0.064 | ||

Square wire lock pin is a type of fastening device used to secure other fasteners like bolts or nuts, or to hold parts of machinery in place. Unlike traditional pins, which may use friction or force to remain secure, square wire lock pins often feature a bendable arm or spring-like mechanism. This mechanism allows the pin to be inserted into a hole and lock into place.

The key feature of a square wire lock pin is its square cross-sectional shape, which increases its strength and stability. The square shape ensures a snug fit in the receiving hole, offering more surface contact compared to round pins. These pins are typically made from durable materials like stainless steel, carbon steel, or coated metals, providing strength and corrosion resistance.

● Square Cross Section: The square shape provides better resistance to shear forces and rotational movement compared to round pins, making them ideal for high-vibration environments.

● Self-Locking Mechanism: Many square wire lock pins include a spring-loaded or bendable arm that helps lock the pin securely in place.

● High Tensile Strength: Made from strong metals like stainless or carbon steel, square wire lock pins can handle significant load-bearing applications.

● Easy Installation and Removal: With a simple design, square wire lock pins can be easily inserted or removed by hand, reducing downtime during maintenance.

Material choice has a direct impact on the durability and functionality of the square wire lock pin. The most commonly used materials include:

● Stainless Steel (304 or 316 Grade): Offers excellent corrosion resistance, making it ideal for outdoor, marine, or chemical-heavy environments. The 316-grade stainless steel is even more resistant to corrosion than the 304 grade, and is often used in saltwater or highly corrosive settings.

● Carbon Steel: Known for its high strength, carbon steel is often used in heavy-duty applications. Carbon steel square wire lock pins are sometimes coated (e.g., with zinc or chrome) to resist corrosion.

● Spring Steel: A special type of carbon steel that is processed to be elastic, giving it better resilience under tension and impact.

When choosing a material, consider the environmental conditions, required strength, and whether corrosion resistance is necessary for your application.

Square wire lock pins are often used in load-bearing applications, so it’s important to understand the load capacity or shear strength of the pin. This capacity will vary based on the material, diameter, and length of the pin.

For example:

● 1/8-inch square wire lock pins made from stainless steel typically have a shear strength of around 1,500 lbs.

● 1/4-inch square wire lock pins can handle shear forces of up to 4,000-5,000 lbs depending on the material.

● 3/8-inch pins may have a load capacity upwards of 10,000 lbs, making them suitable for heavy-duty machinery or construction equipment.

Always ensure the pin you select has the appropriate load-bearing capacity for your application. Exceeding this limit can lead to equipment failure and safety risks.

In addition to material, the finish or coating of a square wire lock pin affects its longevity and performance. Here are some common finishes:

● Zinc-Plated: Adds a layer of corrosion resistance, making it suitable for outdoor use but less durable than stainless steel.

● Galvanized: A more durable type of zinc coating that protects against rust, especially in wet environments.

● Chrome-Plated: Provides a smooth surface and a sleek, polished look, commonly used in automotive and decorative applications.

Choosing the right finish ensures your pin will withstand the environmental conditions and last longer.

Square wire lock pins come in several styles, each offering different features based on the application:

● Single Loop Style: This style has a simple loop or arm that can be bent over to lock the pin in place. It’s easy to install and remove, making it ideal for temporary or frequent use.

● Double Loop Style: Offers added security with two loops, providing extra resistance against accidental disengagement. This is often used in applications where safety is critical.

● Self-Locking: Some pins feature a spring-loaded mechanism that automatically locks the pin in place after insertion. This offers added convenience and security in high-vibration environments.

Category 1 forged lift arm pins is a replacement lift arm pin that is adjustable and is a category 1. This lift arm pin has an adjustable usable length of 1 3/4 inches. Category 1 forged lift arm pin is made of mild steel and has a yellow zinc plated finish.

Material: mild steel

Finish: trivalent yellow zinc

Forged hitch pins are heavy-duty, durable pins, typically used to attach trailers and various turf and agricultural implements.Forged hitch pins are made by a forging process, which involves shaping the metal through high pressure and heat.Manufactured from forged steel with swivel handle and zinc plated,come with R clip pin or Lynch pin and chain.Inch or Metric pin diameter, custom made is available.

● Forged Hitch Pins 1/2 Inch

● Forged Hitch Pins 5/8 Inch

● Forged Hitch Pins 3/4 Inch

● Forged Hitch Pins 7/8 Inch

● Forged Hitch Pins 1 Inch

● Forged Hitch Pins 1-1/8 Inch

● Forged Hitch Pins 1-1/4 Inch

● Forged Hitch Pins 1-3/8 Inch

● Forged Hitch Pins 1-1/2 Inch

A top link is the upper centre arm of a tractor three-point hitch which is used to attach implements to the tractor such as ploughs and hay tines.

#Material:Alloy Steel/mild steel

#Finish Type:Powder Coated

The agricultural spare parts top link is made of high-strength material, which is hard and durable, while meeting various size requirements of tractor links, providing users with flexibility to choose the most suitable link.

#Material:Iron/Alloy Steel/mild steel

#Finish Type:Powder Coated