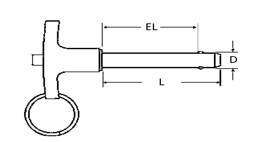

| PART NO. | Nominal(D) | Effective Length | Length (L) | WEIGHT | |

| INCH | MM | INCH | INCH | KG/PCS | |

| T0187-050 | 3/16 | 5 | 1/2 | 0.760 | 0.038 |

| T0187-075 | 3/4 | 1.010 | 0.039 | ||

| T0187-100 | 1 | 1.260 | 0.040 | ||

| T0187-125 | 1-1/4 | 1.510 | 0.041 | ||

| T0187-150 | 1-1/2 | 1.760 | 0.042 | ||

| T0187-200 | 2 | 2.260 | 0.044 | ||

| T0187-250 | 2-1/2 | 2.760 | 0.046 | ||

| T0187-300 | 3 | 3.260 | 0.048 | ||

| T0250-050 | 1/4 | 6 | 1/2 | 0.790 | 0.053 |

| T0250-075 | 3/4 | 1.040 | 0.055 | ||

| T0250-100 | 1 | 1.290 | 0.057 | ||

| T0250-125 | 1-1/4 | 1.540 | 0.059 | ||

| T0250-150 | 1-1/2 | 1.790 | 0.060 | ||

| T0250-175 | 1-3/4 | 2.040 | 0.062 | ||

| T0250-200 | 2 | 2.290 | 0.064 | ||

| T0250-250 | 2-1/2 | 2.790 | 0.067 | ||

| T0250-300 | 3 | 3.290 | 0.071 | ||

| T0250-350 | 3-1/2 | 3.790 | 0.075 | ||

| T0250-400 | 4 | 4.290 | 0.078 | ||

| T0312-050 | 5/16 | 8 | 1/2 | 0.830 | 0.063 |

| T0312-075 | 3/4 | 1.080 | 0.065 | ||

| T0312-100 | 1 | 1.330 | 0.068 | ||

| T0312-125 | 1-1/4 | 1.580 | 0.071 | ||

| T0312-150 | 1-1/2 | 1.830 | 0.074 | ||

| T0312-200 | 2 | 2.330 | 0.080 | ||

A T-handle quick release pin is a type of fastener commonly used in applications where a secure, yet easily detachable, connection is needed. It allows for fast and tool-free removal or insertion, making it ideal for scenarios that require frequent adjustments, maintenance, or

disassembly.

Here are the main features of a T-handle quick release pin:

T-shaped handle provides a comfortable grip and leverage, allowing users to easily pull or push the pin without needing tools.

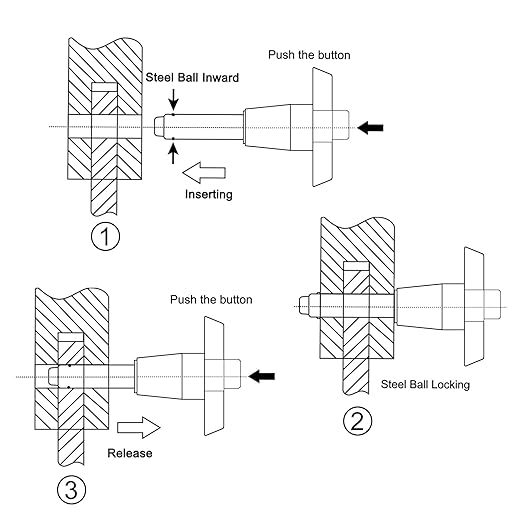

Once the pin is inserted, it is locked into place to ensure a secure connection. The locking mechanism usually involves a ball detent or a similar feature that prevents the pin from coming loose during operation.

This ensures that the parts being fastened remain securely in place even under vibration or external forces.

T-handle quick release pins are typically made from high-strength materials like stainless steel, aluminum, or other alloys. This ensures they are resistant to wear, corrosion, and deformation, making them suitable for demanding environments such as industrial, aerospace, automotive, and military applications.

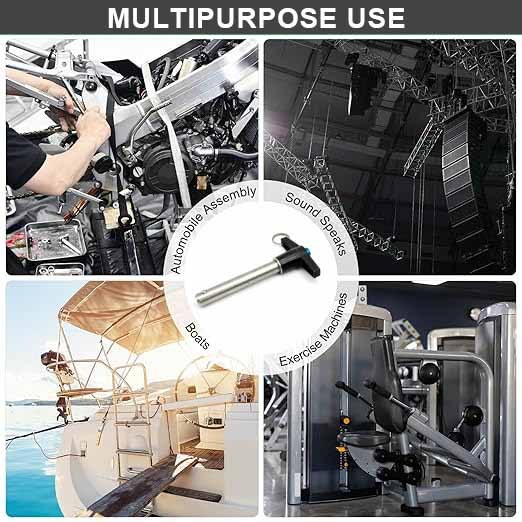

These pins are used in a variety of applications, including machinery, vehicles, aircraft, construction, and military equipment. They are useful in any situation

that requires components to be securely fastened but also need to be quickly and safely detached when necessary.

The design ensures that users can operate the pin without requiring excessive force, reducing operator fatigue and improving overall productivity.

The T-handle quick release pin is a versatile and widely used fastening device, especially in environments where components need to be secured but also quickly and safely detached without tools.

Below are some key applications of T-handle quick release pins across different industries:

Vehicle Maintenance: In automotive repair shops, these pins are used for easy removal of car body parts, like bumpers, fenders, or engine components that require regular servicing.

Boat and Yacht Rigging: On sailing vessels or motorboats, these pins are often used to secure rigging, such as mast attachments, sail components, and removable deck fittings. This allows for quick reconfiguration or maintenance of the vessel's equipment.

Marine Equipment: T-handle pins can be found securing parts on marine engines, trailers, and other systems where tool-free fastening is beneficial.

Stage Rigging: In film, theater, or live event production, these pins can be used to secure sets, lighting rigs, and other equipment that requires fast assembly and disassembly.

Camera Mounting: Quick release pins can also be used to secure cameras, lenses, and other film equipment to tripods or rigs, allowing for fast repositioning or removal during shoots.

Machinery Components: In industrial machines, T-handle quick release pins can be used for securing tooling, guards, covers, or interchangeable parts. This facilitates fast replacement, maintenance, and changeover in production lines.

Heavy Equipment: On construction machinery like excavators, bulldozers, and cranes, quick-release pins secure parts such as attachments, buckets, and tools. The quick release feature ensures that parts can be swapped out without the need for additional tools or extended downtime.

Material Handling: In warehouses or factories, T-handle quick release pins may be used in conveyors, hoists, and other material handling systems for easy attachment or removal of components.

Farm Machinery Attachments: In agriculture, T-handle quick release pins are used to secure attachments on tractors, plows, harvesters, and other machinery. These allow operators to quickly change out tools or equipment depending on the task at hand.

Streamline Your Operations with T-Handle Quick Release Pins!

Whether you need to make quick changes in your production line, simplify equipment maintenance, or improve modular design, our T-handle quick release pins can provide you with efficient and reliable solutions to help your business improve efficiency.

Contact us now to learn more about the advantages of T-handle quick release pins and let us drive your productivity improvement together!

The Category 1 Adjustable Top Link provides a reliable connection between your tractor and implements. With an adjustable length from 17.5 to 26 inches and yellow zinc plating for rust resistance, it’s a durable and essential tool for various farm tasks.

#Adjust Length : 17 1/2", Body Length : 13", Overall Length : 26"

#Category : 1

#Material : Alloy Steel

Twist Lock Plunger Pins are precision - engineered fasteners. They feature a unique twist - lock mechanism for easy and secure installation. Ideal for applications requiring quick assembly and disassembly, ensuring reliable component retention.

# 2 1/2" Twist Plunger Pins/Bolt

# 3" Twist Plunger Pins/Bolt

# 3 3/4" Twist Plunger Pins/Bolt

Customized

Forged lift arm pins is a replacement lift arm pin that is adjustable and is a category 2 to 3. This forged lift arm pin is made of mild steel and has a yellow zinc plated finish.Suitable for agricultural equipment, construction machinery, etc.

Material: mild steel

Finish: trivalent yellow zinc