| Part Number |

Pin Dia. A mm |

Drill Dia. B mm |

Drill Dia. C mm |

Usable D mm |

Usable E mm |

Weight lbs. |

Popular Code |

| P60-18 | 28.57 | 36.50 | 11.90 | 101.60 | 114.30 | 3.78 | 03039 |

| P60-19 | 28.57 | 36.50 | 11.90 | 92.07 | 107.95 | 3.40 | P7250 |

| P60-60 | 22.00 | 28.00 | 12.00 | 34.00 | 122.00 | ||

| P60-61 | 22.00 | 28.00 | 12.00 | 34.00 | 112.00 |

The main feature of Dual Category Clevis Pins is their versatile design, which allows them to be used in multiple applications or with various types of components. They are typically designed with two distinct categories of compatibility, such as different pin diameters or lengths on either end, making them suitable for a broader range of assembly needs. This can offer improved flexibility in installations and repairs, reducing the need for multiple types of pins in inventory

Dual - part Construction: They are designed as two distinct parts that work together. This allows for more flexibility in installation and adjustment compared to traditional single - piece clevis pins.

Precise Fit: The parts are often machined to very tight tolerances, ensuring a secure connection when assembled. For example, the diameter of the pin and the corresponding holes in the clevis may have a tolerance range of ±0.01 mm.

High Strength: Made from materials like high - strength steel. These materials can withstand significant tensile and shear forces. For instance, a well - made dual - category clevis pin can support a tensile force of up to several tons depending on its size.

Corrosion Resistance: Some are coated with zinc plating or other anti - corrosion treatments. This extends their service life in harsh environments, such as outdoor applications exposed to moisture and chemicals.

Easy Installation and Removal: The dual - part design makes it easier to insert the pin into the clevis, especially in situations where there is limited space for a one - piece pin insertion. And during maintenance or replacement, it can be disassembled more conveniently.

Adjustability: Allows for minor adjustments in the connected components. For example, in a mechanical linkage system, it can compensate for slight misalignments between parts.

Dual category clevis pins are widely applied. In the automotive field, they connect suspension parts like control arms to the chassis, ensuring stable driving. In construction, they are used in excavator booms for strong and flexible connections. Industrial machinery such as conveyor systems rely on them to join links or attach components. In aerospace, they play a role in aircraft landing gear and control surface attachment for safety. Also, in shipbuilding, they are used for rigging systems and connecting hatch covers, providing reliable fastening solutions across different industries.

In vehicle suspensions, they are used to connect components like control arms to the chassis or steering knuckles. This helps in maintaining proper wheel alignment and handling characteristics. For example, in independent front suspension systems, dual - category clevis pins ensure that the upper and lower control arms can move freely while keeping the suspension stable.

For attaching brake calipers to the brake rotor or wheel hubs. The pins provide a secure connection that can withstand the high forces generated during braking.

On excavators, they are used in the boom and arm assemblies. As the excavator digs and lifts heavy loads, the dual - category clevis pins keep the boom and arm sections properly connected, allowing for smooth movement and accurate operation.

In cranes, they can be used to attach the jib (the long horizontal arm) to the crane's main structure or to connect different parts of the jib itself.

In conveyor systems, they are used to connect links in the chain or to attach components like pulleys or idler wheels to the conveyor frame. This ensures the smooth operation of the conveyor, especially when handling heavy loads or operating at high speeds.

For securing gears and shafts in machinery such as lathes, milling machines, and gearboxes. The dual - category clevis pins help in maintaining proper gear meshing and shaft alignment.

Discover the difference at Linkgo Farm, where cutting-edge technology meets unmatched craftsmanship. We are dedicated to providing the highest-quality products, produced with precision and delivered on time—every time. Whether you need custom solutions, eco-friendly options, or industry-leading reliability, we’re here to help your business thrive.

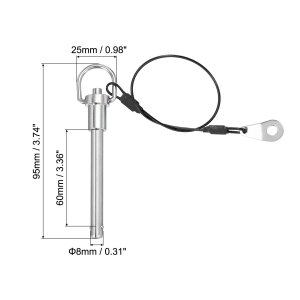

Ring handle positive lock pins, commonly called push button pins or quick release pins, are self-locking quick release pins. They feature a button that engages an internal spring and plunger assembly to operate a detent ball seated at the opposite end of the pin.

#Handle and shank are stainless steel.

#Button is brass or stainless steel.

#Customization is available.

The Category 1 Adjustable Top Link provides a reliable connection between your tractor and implements. With an adjustable length from 17.5 to 26 inches and yellow zinc plating for rust resistance, it’s a durable and essential tool for various farm tasks.

#Adjust Length : 17 1/2", Body Length : 13", Overall Length : 26"

#Category : 1

#Material : Alloy Steel

Clevis Hitch Pin & Roll Pin is made of mild steel with zinc-plated surface,This hitch pin is for use with implements with yoke type mountings.suitable for agricultural equipment, construction machinery

#material:mild steel

#Yellow Zinc Plated or Bright Zinc Plated

The Stainless Steel M8/M12 Antiluce Truck Drop Lock Pin is a high-quality product. Made of stainless steel, it offers excellent corrosion resistance. Available in M8 and M12 sizes, it ensures secure locking for trucks. Its precise design guarantees reliable performance, providing a safe and dependable solution for truck locking mechanisms.

#Come with Nut and Washer per request

#Zinc Clear or Zinc Yellow plated.

#Inch or Metric thread size.

#Low Carbon steel or Stainless Steel material.